Surface Preparation

Surfaces should be clean and dry if FixMaster Adhesive Mastic is being used, badly dished or holed concrete should ideally be filled.

If application is to damp, dirty or friable surfaces or in very cold weather, use FixMaster Adhesive Mastic to bed the GRP item into place and then always screw fix. Screw fixings are generally made at 300mm intervals. Drilling through the GRP is easy using a standard twist drill suitable for wood or metal. Countersinking is not required.

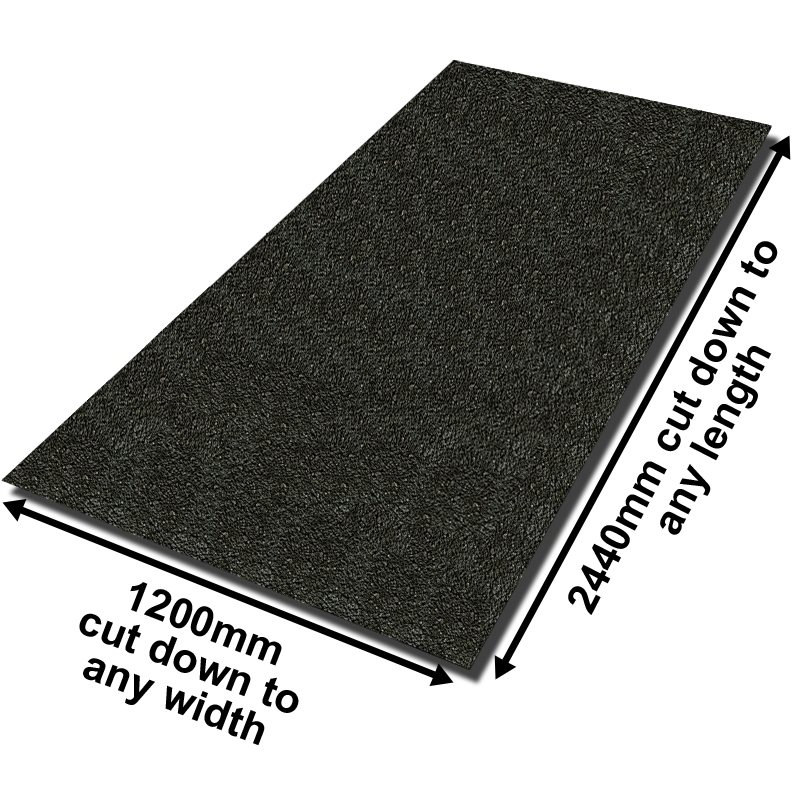

If you need to cut the GRP product, a good quality abrasive disc, jigsaw or hacksaw can be used. The GRP material is quite tough to cut by hand, so if power tools are not readily available, please ask about our cut to size service.

Fixings

If mechanical fixing is required, the following may be used as a guide:

- To timber: No.8 x 30mm zinc plated or stainless steel screws.

- To steel plate: No.8 x 20mm self-tapping pan head Pozi stainless steel screws or No.8 x 20mm self drilling pan head Philips zinc plated screws.

- To concrete: No.8 x 30mm zinc plated or stainless steel impact anchors (Hilti HPS-1 or similar).

- To open mesh: Stainless steel or zinc plated saddle clips and domed head bolts suitable in length for the depth of the existing treads.

Application

Lay the items in place to ensure that they fit and trim using a jigsaw with medium cutting blades.if necessary.

Hold the GRP in place and drill a hole at each corner, a rawlplug will probably be required in a concrete base. The drill hole in the GRP does not need to be larger than that drilled into the substrate. FixMaster Adhesive Mastic is also a sealer and can be used around the edge of the sheet to prevent water lying underneath the sheet.

Reviews

There are no reviews yet.