Resin Bound vs Resin Bonded Gravel for drives and paths

There are two different systems that use resin to fix gravel aggregates, resin bound and resin bonded.

Resin Bound systems are porous and SuDS (Sustainable Urban Drainage Systems) compliant when used with the appropriate aggregate. The resin bound mixture has open voids across the surface, allowing air to flow freely and surface water to filter through the structure. This makes it ideal for driveways, paths, tree pits and any areas which normally would be prone to flooding or standing water. In resin bound surfacing the aggregate is mixed with the resin and the material is then trowelled down to a smooth finish similar to a screed (with no loose stones). It is recommended that a resin bound surface should be laid to a depth of 15mm for a pool surround, footpath or terrace and 18mm for a driveway and car park. When this is set there are no loose stones and it features a smooth surface finish.

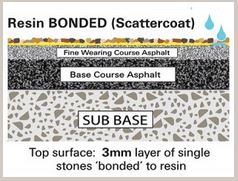

Resin Bonded systems are non-porous. Resin bonded surfacing is a scatter system which provides texture and the appearance of loose gravel. It is non-porous so water will not filter through the surface. A layer of resin applied to a suitable surface is applied and covered with loose aggregate. Once cured the remaining loose stones are removed by sweeping the surface. Thickness is governed by aggregate size. i.e. 1-3mm aggregate will have a nominal depth of 4mm. This surface must be laid directly onto a non-porous fine wearing course tarmac or concrete base and with resin bonded gravel surfaces it is important that proper drainage is installed to prevent flooding

Resin Bonded is a low-cost option for giving a surface a new lease of life; although it is important to note that the bonded aggregate particles could loosen over time. This surface is also not very easy to clean although when professionally installed it can transform a space instantly.

Download this page as a PDF for future reference!