Mixing

By weight or volume = 2 part resin to 1 part hardener

Note:

The mixing ratio must be accurately followed, it is not possible to change the ratio as this would result in lower mechanical properties and the resin not drying properly. Pour the required amount of hardener and resin into a large container and stir for 3-5 minutes until the components are completely mixed. Epoxy systems heat up much faster in a pot than as a thin film, so it is important to pour immediately, mix only what is needed within the 60 minute pot life

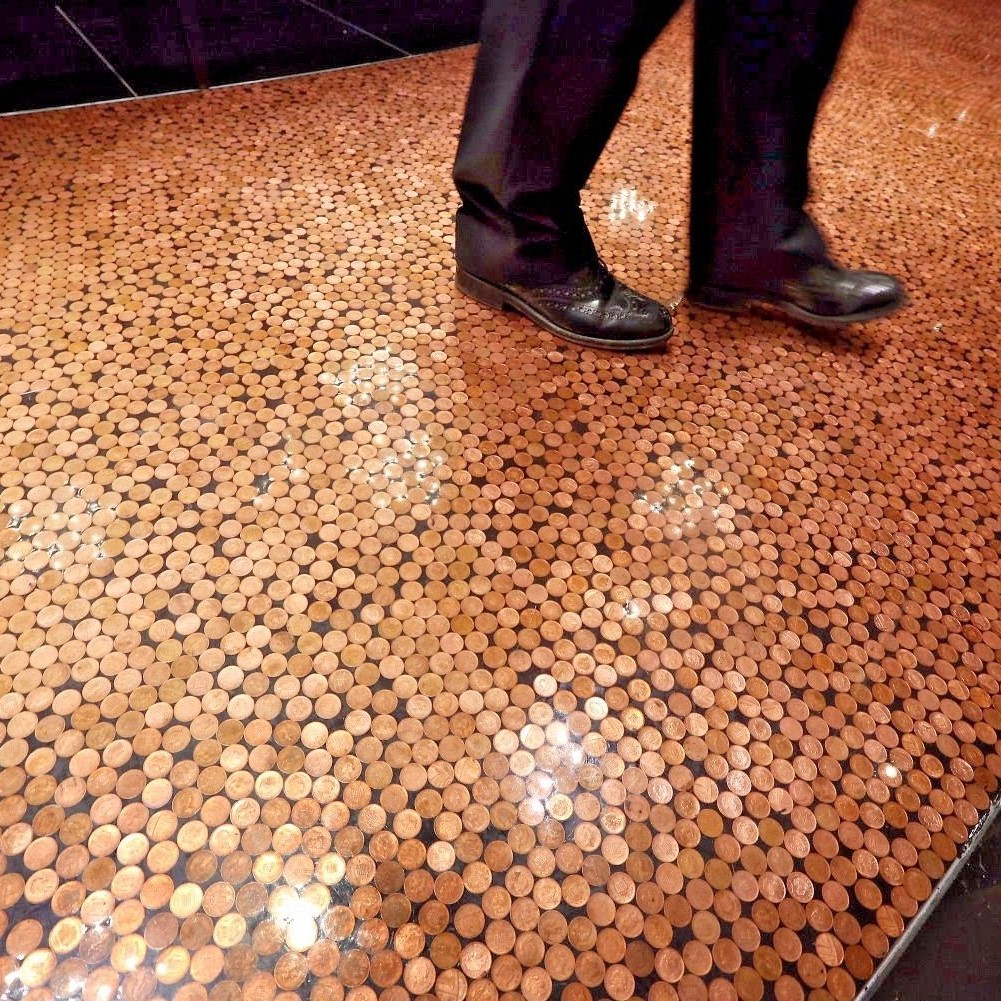

Application

Apply by hand, pouring and moving with trowel or similar. FixMaster Table Top Resin can also be coloured with tints for individual finishes. Ensure the surface is level as the product is initially very thin and will run on a slope. Pours should be no thicker than 5mm.

After pouring, warm air can be passed over the surface to release the trapped air, the heat source should be kept at a distance of approximately 30cm. Do not overheat the surface imperfections could be left. A standard heat gun is advised as hairdryers or blowtorches can create ripples. Keep the heat moving and do not concentrate one area for too long. Keep dust at a minimum in the surrounding areas for at least 24 hours as dust may imbed itself into the uncured resin.

Overcoating

If further coats are required, leave a minimum of 3 days and lightly abrade the surface of the previous pour.

Bubbles

Any bubbles created by hand-mixing can be easily popped by using a sharp object or by passing warm air over the surface of the resin (e.g using a blowtorch or hot air dryer on slow speed setting).

Blowtorch

Don’t hold the blowtorch or hot air blower closer than 30 cm to your artwork otherwise you risk creating ripples and dimples in the resin finish.

Dust

You will need to protect the area from dust accumulation for at least 12-24hrs, try to avoid cross draughts while the area is drying.

Reviews

There are no reviews yet.